Exhaust gas absorption system

Exhaust gas absorption system

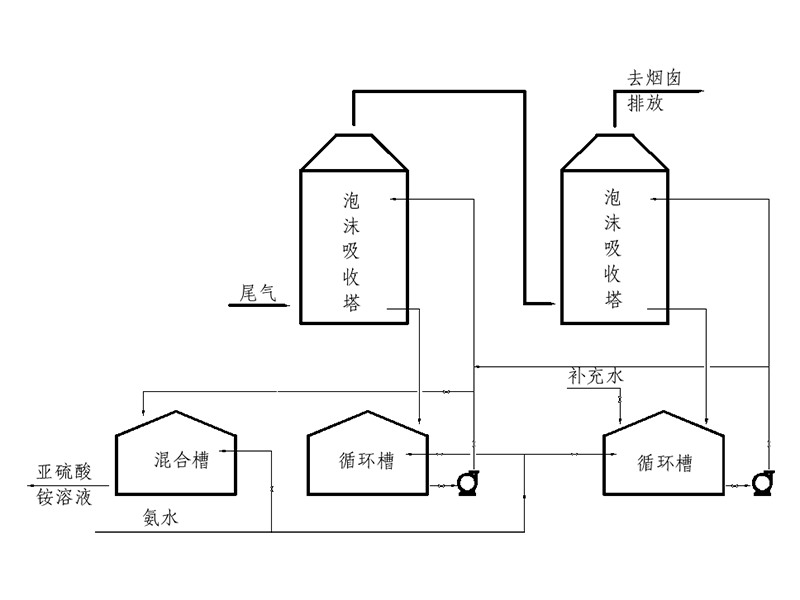

In industries such as sulfuric acid plants, smelters, power plants, and fertilizer plants, the production tail gas contains a large amount of toxic substances, which need to be reused or discharged after the tail gas is absorbed and treated. At present, the commonly used tail gas recovery processes mainly include the ammonia method and the sodium method. The ammonia method includes the two-stage ammonia method in the foam tower, the pipeline-type multiple injection and multiple block two-stage ammonia method, the pipeline-type multiple injection and multiple block three-stage ammonia method, and the ammonium bicarbonate method. It is the raw material two-stage ammonia method and three-stage ammonia method. After the sulfur dioxide tail gas passes through the two-stage ammonia process or the three-stage ammonia process, the concentration of sulfur dioxide in the vented exhaust gas can reach ~200ppm.

The tail suction equipment mainly includes a packed absorption tower, a foam absorption tower, and a compound spray compound absorber. The technical parameters are as follows:

| Serial number | Project | Packed absorption tower | Foam absorption tower | Double injection double block absorption tower |

| 1 | Empty tower operating speed | 0.4~2m/s | 1.5~2.5m/s | 12~14m/s |

| 2 | Spray density | 3~10m3/(m2.h) | 12~18m3/(m2.h) | —— |

| 3 | Absorption efficiency | ~90% | ~92% | ~90% |